The Cross-Docking Advantage for Supply Chains

Ryder Exchange

The supply chain landscape continues to change as the pace to get products to consumers increases. Consumer demand has led to many changes in the supply chain as shippers are trying to get products to market faster. To keep pace, more shippers are turning to cross-docking to reduce the amount of time it takes to process orders, route products, and deliver to customers.

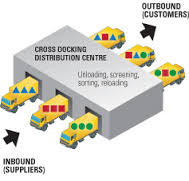

Cross-docking refers to moving product from the receiving dock to the shipping dock with minimal handling and little to no storage. While cross-docking speeds products to their final destination, it also helps supply chains reduce costs. Cross-docking is core to a high functioning supply chain, which is critical for shippers pursuing a LEAN distribution network with just-in-time inventory control.

Many of the biggest retailers have already implemented cross-docking. Walmart instituted the practice in its warehouse and has lowered its cost for inventory storage, reduced transportation costs, and decreased the amount of time products spend in transit.

According to a recent survey conducted by Peerless Media with the support of Ryder, approximately half of today’s shippers use cross-docking. However, 40 percent of those surveyed are not familiar with cross-docking or don’t plan on implementing the practice.

Cross-docking benefits many aspects of the supply chain. It can reduce on-hand inventory, streamline processes, and help improve end-to-end visibility across the supply chain – all three of which are top concerns of supply chain managers surveyed by Peerless Media.

Operating an effective cross-docking strategy does not come without its challenges, especially at a time when supply disruption is prevalent. Rising freight costs, and an inability to adjust activity levels brought on by season peaks are top challenges, along with dock scheduling and availability, and limited storage capacity.

Cross-docking brings inherent issues and risks, especially for organizations that haven’t considered it in the past. Cross-docking requires personnel skilled in the coordination of inbound and outbound transportation, as well as the specialized delivery equipment, including sortation equipment and conveyors, needed to transfer goods.

Additionally, some retail locations are not designed or equipped to safely accommodate the increased traffic flow. Handled poorly, cross-docking could lead to increased product damage and safety risks. Shippers who have not explored cross-docking in the past should discuss the benefits of cross-docking with a 3PL provider with the right facilities, processes, and personnel.

As consumer demand continues to put pressure on shippers to speed products to market, a cross-docking solution can meet those demands. Not only does cross-docking improve efficiency and cut costs, but it also gives shippers a distinct advantage over competitors who rely on traditional practices.

http://blog.ryder.com/2016/02/the-cross-docking-advantage-for-supply-chains/